These grate bar are used in the furnace upon which the fuel is burned. These bars are manufacture with various alloy compositions, depends on the fuel used in the boiler. The intermittent gap in the grate bar / fire bars allows the air flow for combustion. Proper selection of the gap is necessary to avoid the fuel from falling down, while burning.

Grate Bars (Boiler Grate Bars) are critical components used in the combustion zone of boilers where solid fuel is burned. These precision-cast components are engineered to withstand intense heat and mechanical stress inside the furnace. Manufactured using CI (Cast Iron), SG Iron (Spheroidal Graphite Iron), SS (Stainless Steel), and Heat-Resistant Alloys, these Grate Bars are tailored as per the fuel type and combustion conditions. Their optimized gap design ensures efficient air flow while preventing unburnt fuel from falling through. These rugged and durable Grate Bars enhance thermal efficiency, improve combustion, and extend furnace life.

Salient Features :

Applications :

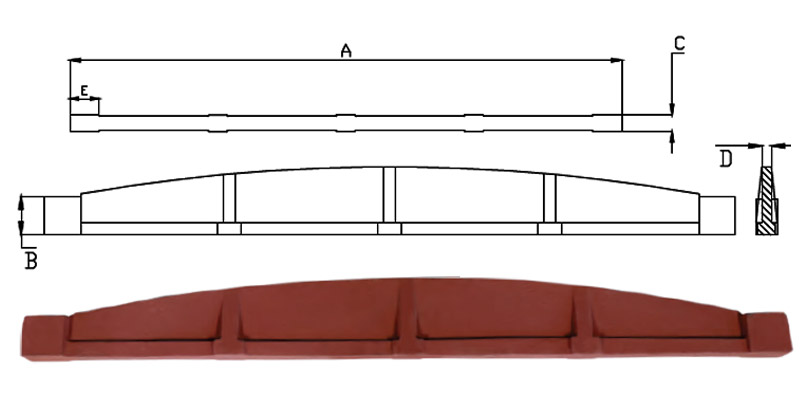

| DIMENSIONS IN MM | |||||

| SR NO | A | B | C | D | E |

| G1 | 530 | 45 | 32 | 12 | 36 |

| G2 | 890 | 47 | 32 | 12 | 47 |

| G3 | 822 | 45 | 32 | 8 | 45 |

| G4 | 730 | 50 | 32 | 8 | 45 |

| G5 | 1010 | 50 | 32 | 8 | 45 |

| G6 | 540 | 45 | 35 | 12 | 50 |

| G7 | 615 | 45 | 35 | 12 | 50 |

| G8 | 690 | 45 | 35 | 12 | 50 |

| G9 | 578 | 45 | 32 | 12 | 55 |

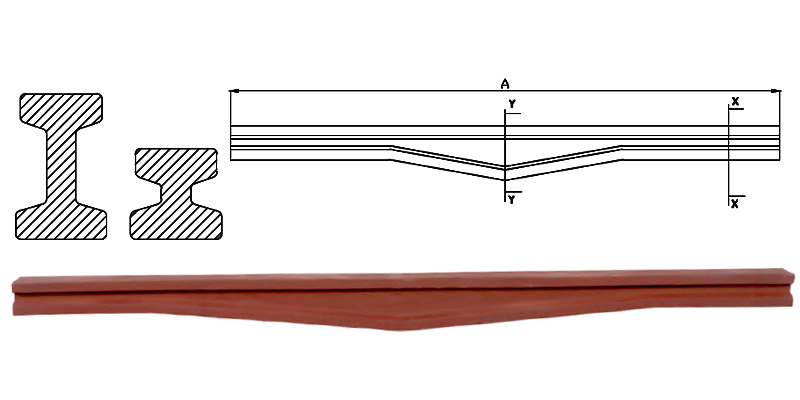

| DIMENSION IN MM | |

| SR NO | A |

| S1 | 740 |

| S2 | 1066 |

| S3 | 1422 |

| S4 | 1132 |

| S5 | 940 |

| S6 | 1280 |

| S7 | 1120 |

| S8 | 800 |

| S9 | 1150 |

| S10 | 1030 |

| S11 | 930 |

| S12 | 1308 |

| S13 | 642 |

| S14 | 860 |

| S15 | 980 |

| S16 | 1010 |

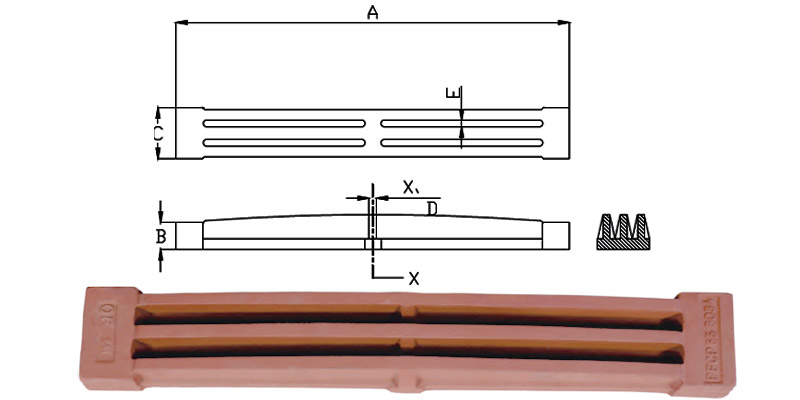

Modified version of single grate bar. Basically three grates bars are combined and manufactured as one piece. A homogeneous construction, allows, more heat dissipation, resulting in better heat resistance. These grate bars generally give a longer life.

| DIMENSION IN MM | |||||

| SR NO | A | B | C | D | E |

| T1 | 730 | 50 | 96 | 15 | 10 |

| T2 | 530 | 50 | 96 | 15 | 10 |

| T3 | 630 | 50 | 96 | 15 | 10 |

| T4 | 690 | 45 | 105 | 15 | 15 |

| T5 | 540 | 45 | 105 | 15 | 15 |

| T6 | 615 | 45 | 105 | 15 | 15 |

| T7 | 690 | 45 | 90 | 15 | 8 |

| T8 | 615 | 45 | 90 | 15 | 8 |

| T9 | 615 | 45 | 96 | 15 | 10 |

| T10 | 540 | 50 | 90 | 15 | 8 |

| T11 | 540 | 50 | 96 | 15 | 10 |

| T12 | 578 | 50 | 90 | 15 | 8 |

| T13 | 578 | 50 | 96 | 15 | 10 |